The ore powder and granulated blast furnace slag powder is a high-fineness.

high-reactivity powder material obtained by quenching blast furnace slag with water, and after being processed by drying and grinding.

it is not only a high-quality concrete admixture and a cement mixing building material.

but also that’s world recognized as an important material for configuring high performance concrete.

The incorporation of slag at a certain proportion in cement production is a component of the slag portland cement, which can improve the performance of the cement and reduce the production cost and energy consumption.

The use of slag with moderate or excessive amounts of ready-mixed concrete and cement products can improve the performance of concrete and is a high-quality mixed building material.

Slag raw materials

Mineral powder finished product

After partially replacing clinker

After partially replacing cement

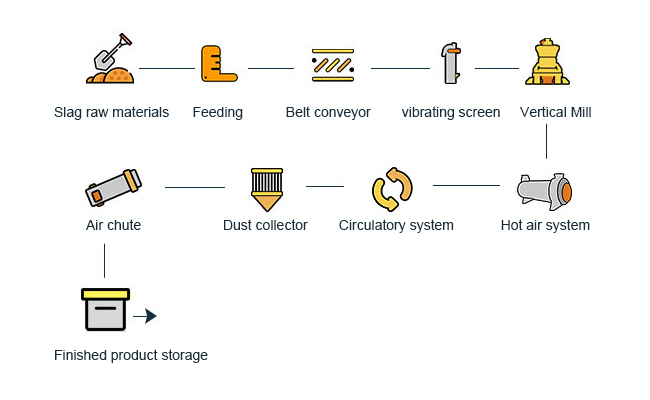

The slag raw material is taken by a forklift and fed, and conveyed by a belt conveyor. During the conveying process, the slag raw material is then iron-removed and sieved through the iron remover and the vibrating sieve, and then it is pulverized by the elevator into the VM vertical milling machine. The slag after grinding is hot-air supplied by a hot blast stove, and the powder is selected by a separator and dried at the same time. The slag powder that meets the fineness requirements is finally transported to the dust collector for collection and containment, and then transported by an air transport chute and elevator into the finished product warehouse for storage.

VM slag vertical mill is a special equipment for industrial waste slag milling. It integrates crushing, drying, grinding, grading and conveying. It has a simple system and a compact layout. It covers an area of about 50% of the ball milling system and can be arranged in the open air. A large number of investment costs are reduced; and the grinding roller directly grinds and grinds the material on the grinding disc, which has low energy consumption and saves 30% to 40% of energy consumption compared with the ball milling system.

If there are any questions concerning the stone crushing & screening plant, please contact Kefid directly.

Our engineers will provide the professional solution. Welcome to visit our factory in Zhengzhou city, Henan province, China.

: 0086-371-67988500 / 67999255 / 86537170(24 hours)

: sales@kefidgroup.com

: KFD_onlineservice

: kefidcrusher

: No.169, Kexue Avenue,National HI-TECH Industrial Development Zone,Zhengzhou, China