NEWS

- Company News

- Kefid's impact crusher models

- Kefid single-cylinder hydraulic

- The equipment configuration and

- The future development of minin

- K series tire mobile crusher

- Bauma China 2020: Three new pro

- Basalt sand and gravel producti

- The crushing mechanism of impac

- The use of coal gangue and crus

- 325 mesh calcium carbonate powd

- Industry News

- The maintenance measures that i

- The standard of mechanism sand

- The technological processes of

- The technical advantages of Eur

- Concrete blocks recycling to bu

- A powerful tool for processing

- Stone crusher for railway proje

- The selection of crushing cavit

- The advantages of mobile sand m

- The solution to prevent corrosi

- Exhibition

- Special Report

- Faq

- How to maintain the production

- How to configure equipment for

- The composition of cement raymo

- I want to buy a coal mill with

- What equipment is needed for th

- What are the complete sets of e

- Regarding the waste disposal af

- What is the price of sand washe

- How much are the accessories of

- What is the reason for the slow

Basalt sand and gravel production line configuration

Basalt is a basic extruded rock, the main components are silicon dioxide, aluminum oxide, iron oxide, calcium oxide, magnesium oxide (and a small amount of potassium oxide and sodium oxide), and the content of silicon dioxide is relatively high. It accounts for about 45% to 52%.

Basalt has high silicon content, hard texture and good compressive strength. It is a high-quality sand and gravel aggregate raw material, but it is also difficult to break in stone and requires high rigidity of the machine. If the equipment is not selected properly, the wearing parts will be severely worn and the processing effect will be poor during use. Therefore, in the equipment configuration of the basalt sand and gravel production line, the crushing equipment of the lamination principle should be used as much as possible to reduce the production loss of the equipment.

Basalt sand and gravel production line generally adopts three-stage or four-stage crushing configuration:

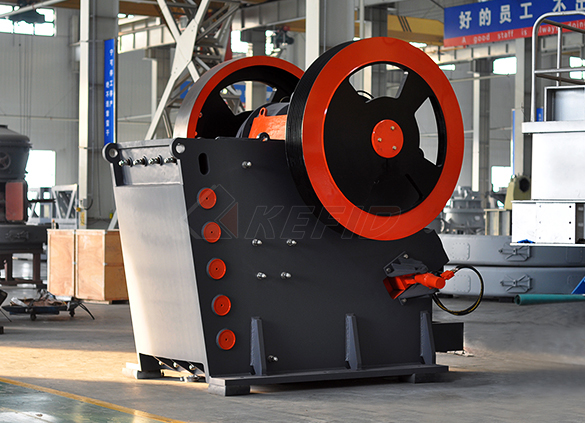

1. Primary crushing-coarse crushing

The size of the stone mined from the mountain is relatively large, and it needs to be crushed first. The machine used is usually jaw crusher. The jaw crusher can crush large stones to a medium size (about 10-30cm) at a time.

2. Two-stage crushing-medium to fine crushing

Basalt has high hardness and difficulty in crushing. In the selection of medium and fine crushing equipment, hydraulic cone crusher that adopts the principle of laminated crushing is usually selected. The crushing effect between materials is used to reduce impact and wear on machine parts.

The double cone crusher combination of single-cylinder hydraulic cone crusher + multi-cylinder hydraulic cone crusher can be used to share the loss of the machine, optimize the stone grain shape and achieve greater output.

3. Three-stage crushing-shaping sand

If you want to further break the stones into mechanism sand, you can add a three-stage crushing link, that is, the shaping sand making link, which can not only reshape the stones, but also break some needle-shaped stones and waste materials with bad grains into mechanism sand, one production line can produce sand and stone at the same time.

For high-hardness stones such as basalt, the sand making equipment mostly uses vsi crusher. Using the principle of "stone hit stone", the impact force between the stones is used to achieve the purpose of further crushing.

Why does the basalt sand and gravel production line configuration plan do not use impact crusher, hammer crusher and roller crusher? This is also determined by the hardness and strength of the basalt material, or the slab hammer, hammer head, roller are vulnerable to damage during subsequent operation. The wear of the parts is too large, and the frequent replacement of wearing parts is expensive.

With the production line configuration of jaw crusher + cone crusher + vsi crusher, although the initial project investment cost is slightly higher, for the long-term operation of the sand and stone yard, the third and fourth stage crushing is more worry-free and money-saving in the later stage, and the later operation is reduced.

For more details and equipment quotation, please contact our 24hour online customer service.